HOW DOES XRF WORK?

X-Ray Fluorescence Spectroscopy, uses the refraction pattern of X-rays to determine the elemental composition of complex materials.

Steps:

EXCITATION: The sample material is exposed to X-rays. The X-ray energy is absorbed by lower-orbital electrons, causing them to eject from the atom entirely.

EMISSION: Higher-orbital electrons dump energy to fill in the gap left in the lower orbit.

DETECTION: The fluorescent X-rays emitted by this energy dump is detected by the device detector.

ANALYSIS: Each element has a unique X-ray emission pattern. Our digital signal processors and XRF algorithms work to determine the element ID based on this emitted pattern.

HOW DO OUR DEVICES HELP YOU?

ALLOY ANALYSIS

On-the-spot quality control checks

Identify bad alloy shipments before they cause problems

Save time from laboratory testing

Non-destructive

MINING

Exploration

Survey large areas with immediate results

No need to collect and mark samples for the lab

Ore Analysis

On the spot ore analysis allows veins to be tracked easily

No need to break off samples, testing can be conducted in-situ

ECOLOGICAL SURVEY

Heavy metal contamination detection: lead, arsenic, cadmium, mercury

Large area environmental compliance surveys

Agricultural land fertility surveys

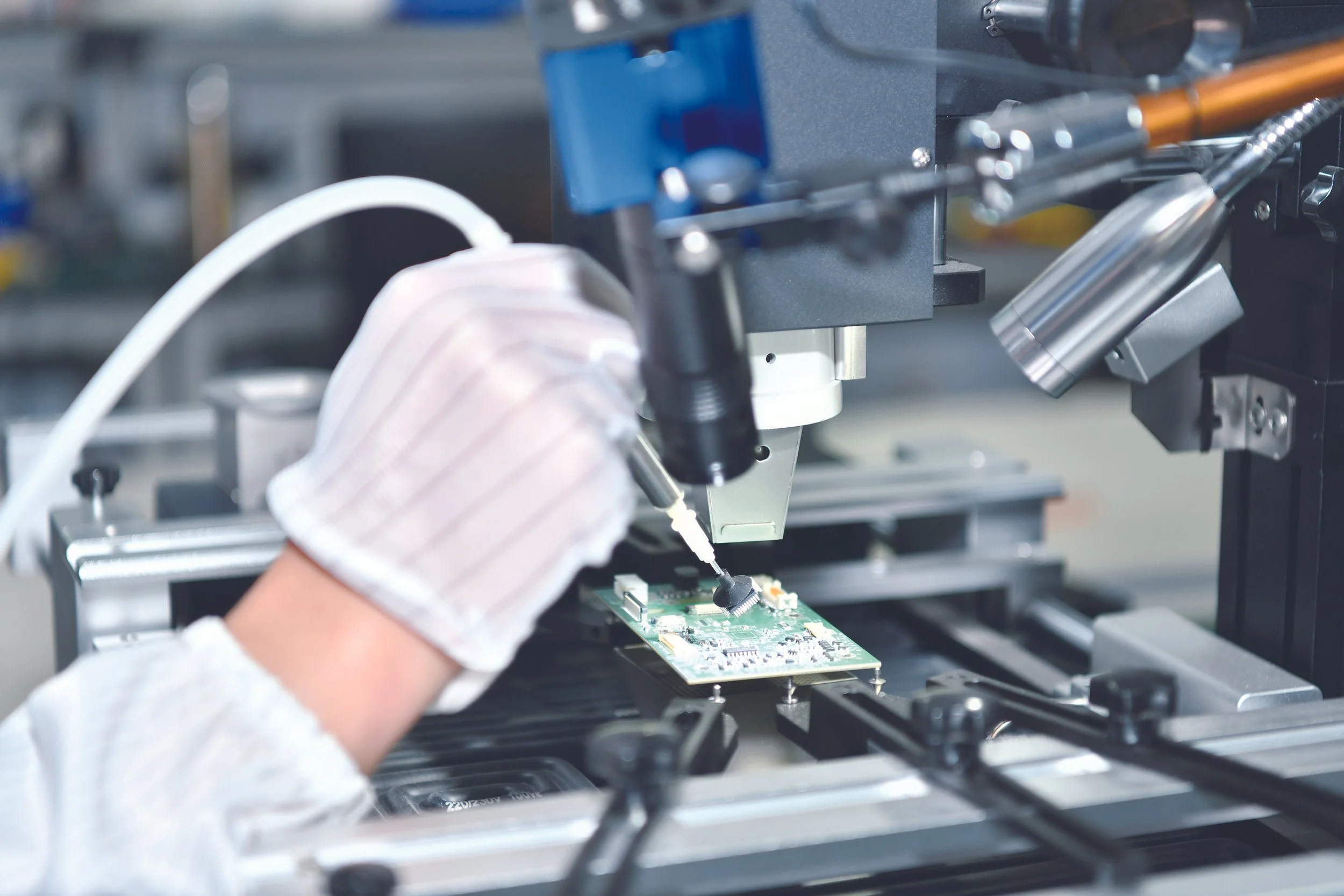

RoHS COMPLIANCE TESTING

Screen for lead, mercury, cadmium, hexavalent chromium, PBB, PBDE and other hazardous materials at levels acceptable by RoHS standards

Non-destructive, essential for high value goods

Screen repeatedly with no need to wait for lab results