Handheld X-ray Spectrometers in the Non-Ferrous Metal Chain

In today's rapidly advancing industrial era, non-ferrous metals play a crucial role as fundamental raw materials in various fields such as aviation, automotive, and electronics. With continuous technological progress, handheld X-ray fluorescence (XRF) spectrometers, known for their efficiency and portability, are becoming an indispensable part of the entire non-ferrous metal industry chain. This article delves into the applications of handheld XRF spectrometers at different stages of the non-ferrous metal industry, revealing how they assist enterprises in achieving precise control and efficient operations.

I. Rapid Screening and Grade Assessment in the Mining Phase

Accurately determining the grade and composition of ore is key to improving resource utilization during the extraction process of non-ferrous metals. Traditional laboratory analysis methods are time-consuming and costly, whereas the advent of handheld XRF spectrometers has revolutionized this aspect. They enable rapid, non-destructive analysis of ore samples directly in the field, providing immediate chemical composition data. This significantly reduces the testing cycle and enhances sample processing efficiency, allowing companies to make quick mining decisions and optimize resource allocation.

II. Real-Time Monitoring and Quality Control During Smelting

Handheld XRF spectrometers also play a vital role in the smelting stage. In critical processes such as melting and refining, timely monitoring of changes in the composition of raw materials and intermediate products is essential for ensuring product quality. Handheld XRF spectrometers can analyze the elemental content of furnace charges and molten metals in real-time, aiding engineers in adjusting process parameters to ensure stability in production and consistency in products. Moreover, they effectively identify and eliminate substandard raw materials, reducing waste in production.

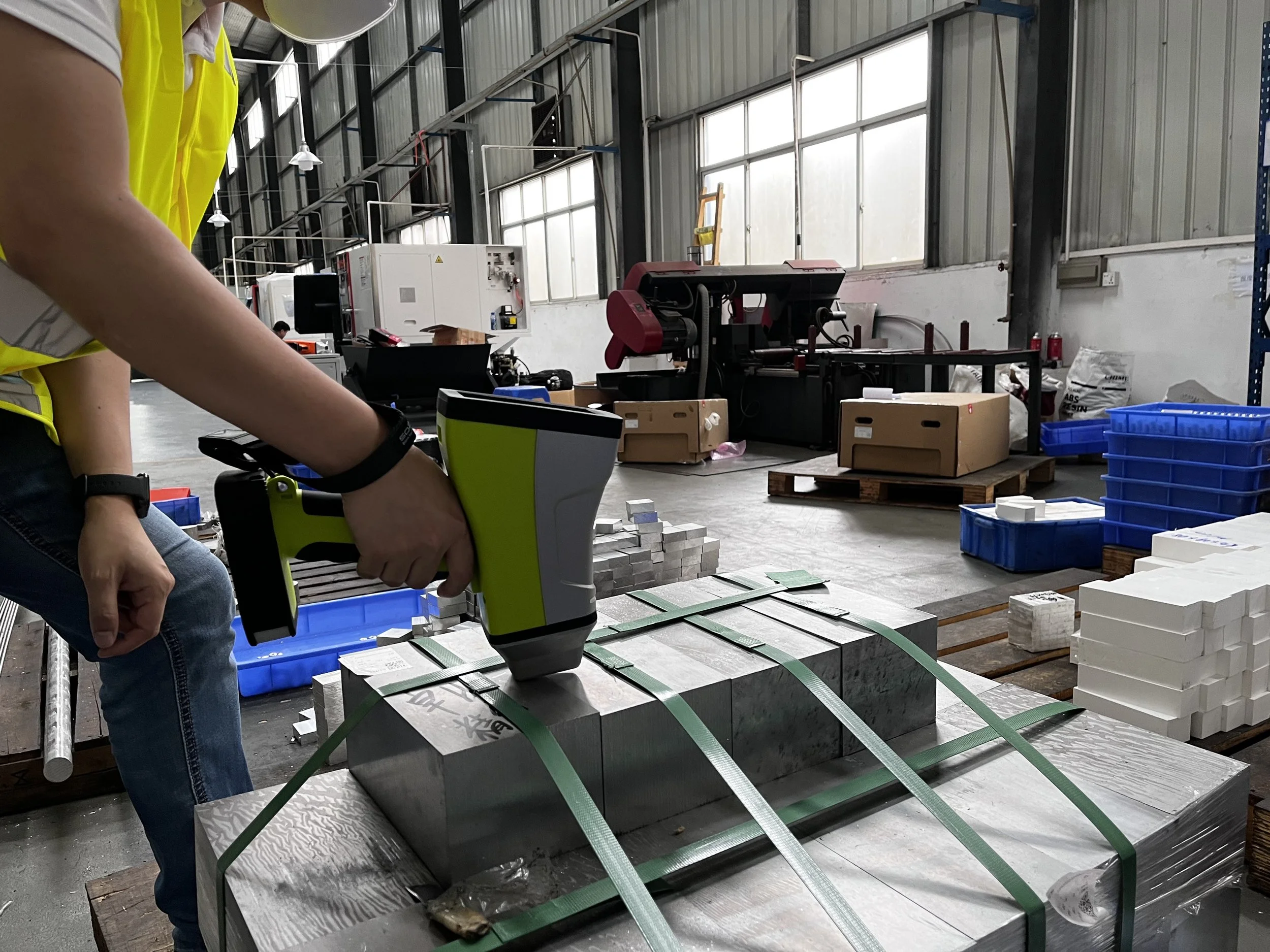

III. Material Verification and Quality Inspection in Processing and Manufacturing

During the deep processing manufacturing stages of non-ferrous metals, such as rolling and extrusion forming, the purity and performance of materials directly impact the quality of the final products. Handheld XRF spectrometers are used to quickly identify material types and verify compliance with production requirements. Additionally, before products leave the factory, they conduct tests on surface coatings and alloy compositions to ensure each item meets industry standards, thus maintaining the corporate brand image.

IV. Impurity Detection and Classification Management in Recycling

With growing environmental awareness, the recycling of non-ferrous metals is gaining increasing importance. At scrap metal recycling stations, handheld XRF spectrometers can rapidly distinguish between different metal types, assessing their recycling value. More importantly, they detect harmful impurities like lead and mercury in metals, preventing these contaminants from causing secondary pollution during the recycling process, thereby promoting green and sustainable development.