XRF Technology Working Principle: An In-Depth Exploration of Fluorescence Spectroscopy Analysis

In modern analytical science, X-ray fluorescence (XRF) technology has become an indispensable tool. This technique utilizes X-rays to excite atoms in a sample, causing them to emit secondary X-rays (i.e., fluorescence X-rays), thereby achieving qualitative and quantitative analysis of the sample's composition. This article will provide a detailed introduction to the working principle of XRF technology, its key components, and its workflow.

I. Basic Overview of XRF Technology

The X-ray fluorescence spectrometer (XRF) is an instrument that uses primary X-ray photons or other microscopic particles to excite atoms in the material being tested, causing them to produce fluorescence (secondary X-rays) for material composition analysis. This technology features rapid, non-destructive analysis, a wide analytical range, and high precision, making it widely used in fields such as geology, metallurgy, materials science, and environmental science.

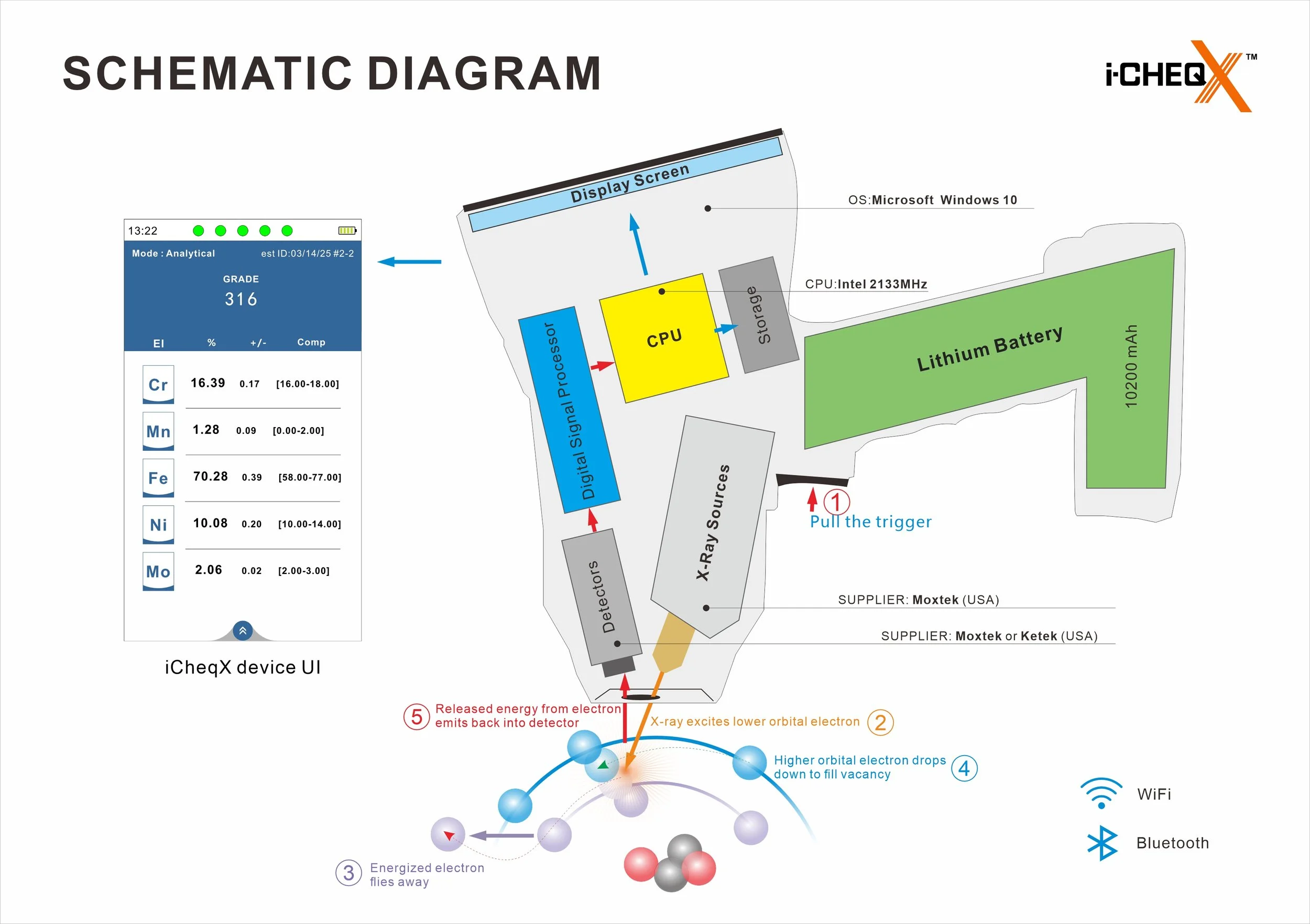

II. Key Components of XRF Technology

X-ray Tube

The X-ray tube is one of the core components of the XRF spectrometer. It is responsible for generating primary X-rays. These high-energy X-rays are used to excite the atoms in the sample, causing inner-layer electrons to be ionized, which triggers subsequent fluorescence phenomena.

Detector

The detector is another key component of the XRF spectrometer, used to detect and measure the fluorescent X-rays emitted by the sample. Depending on the method of dispersion, detectors can be divided into energy-dispersive (EDXRF) and wavelength-dispersive (WDXRF) types.

Energy-dispersive Detectors: Determines the type and content of elements by measuring the energy of the fluorescent X-rays. Common energy-dispersive detectors include proportional counters, scintillation detectors, and semiconductor detectors.

Wavelength-dispersive Detectors: Conduct qualitative and quantitative analyses by measuring the wavelength of the fluorescent X-rays. Wavelength-dispersive detectors are usually used in conjunction with crystal spectrometer systems to improve resolution and sensitivity.

Data Processing System

The data processing system is responsible for collecting signals transmitted by the detector and converting them into data formats suitable for analysis. The system also includes software algorithms to correct background noise, spectral line overlap, and other interference factors, thereby improving the accuracy and reliability of the analysis.

III. Workflow of XRF Technology

The workflow of XRF technology can be summarized into the following steps:

Sample Preparation: Place the sample to be tested in the sample chamber, ensuring the sample surface is clean and flat. For irregularly shaped samples, filters or collimators can be used to define the area to be measured.

Excitation and Emission: The primary X-rays generated by the X-ray tube irradiate the sample, causing the inner-layer electrons of the atoms in the sample to be ionized. When outer-layer electrons jump to inner-layer vacancies, they emit fluorescent X-rays with specific energies.

Detection and Measurement: The detector receives and measures the fluorescent X-rays emitted by the sample. For energy-dispersive detectors, this involves measuring the energy of the X-rays to determine the type of element; for wavelength-dispersive detectors, this involves measuring the wavelength of the X-rays for qualitative and quantitative analysis.

Data Processing and Analysis: The data processing system collects signals transmitted by the detector and processes them through software algorithms. Ultimately, an analysis result containing information about the types and contents of elements is generated.

IV. Advantages and Application Areas of XRF Technology

Advantages

Non-destructive Analysis: XRF technology does not damage the sample, making it suitable for analyzing precious or non-destructible samples.

Rapid Analysis: The analysis time for each element is usually between a few seconds to several minutes, significantly improving analysis efficiency.

Wide Analysis Range: Capable of analyzing most elements in the periodic table, suitable for various sample types.

High Precision and Reproducibility: High analysis precision and good reproducibility meet the stringent requirements of scientific research and industrial fields.

Application Areas

Geological Exploration: Used for mineral resource exploration to determine the composition and grade of ore.

Environmental Monitoring: Detects heavy metal pollution in soil, water bodies, and the atmosphere.

V. Conclusion

XRF technology plays an important role in multiple fields due to its unique advantages. With technological advancements, the performance of XRF spectrometers continues to improve, broadening their application prospects in elemental analysis. In the future, we can expect XRF technology to demonstrate its powerful analytical capabilities in more emerging fields.